ASSOCIATED ENGINEERS

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to ASSOCIATED ENGINEERS

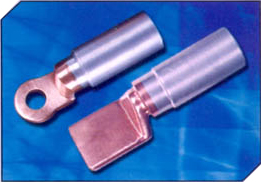

Copper Aluminium Bi Metal Lugs

CONDUCTIVE MATERIAL :

ALUMINIUM BARREL 99.6%

COPPER PALM 99.95%

FINAL METAL STATE FULLY ANNEALED INCLUDING JOINT

JOINING METHOD FRICTION WELDING, WELDING AREA MORE THAN NOMINAL CONDUCTOR AREA.

FINISH NATURAL.

CONDUCTIVITY

ALUMINIUM 61.8% IACS (MIN)

COPPER 99.7% IACS

ALUMINIUM BARRELARE CHEMICALLY TREATED TO REDUCE CONTACT RESISTANCE AND CORROSION AND ARE FILLED ELECTRICALLY CONDCTIVE CORROSION INHABITANT WITH A JOINTING COMPOUND AND CAPPED.

NOTE :

1) COMBINATOINS OF BI-METALLIC COMPRESSION JOINTS ARE DESIGNED ON THE BASIS OF CURRENT CARRYING CAPACITY OF INDIVIDUAL CABLES.

2) IN CASE ADDITIONAL COMBINATIONS ARE REQUIRED SAME MAY WILL BE PROVIDED AGAINST SPECIFIC REQUEST.

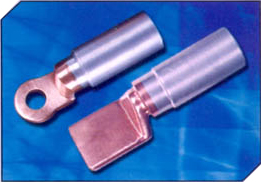

Bimetallic Compression Reducers

CONDUCTIVE MATERIAL :

CONDUCTIVITY :

ALUMINIUM BARREL

99.6% ALUMINIUM61.8% IACS (MIN)

COPPER PALM

99.95% COPPER99.7%IACS

FINAL METAL STATE FULLY ANNEALED INCLUDING JOINT

JOINING METHOD FRICTION WELDING, WELDING AREA MORE THAN NOMINAL CONDUCTOR AREA.

FINISH NATURAL.

ALUMINIUM BARRELARE CHEMICALLY TREATED TO REDUCE CONTACT RESISTANCE AND CORROSION AND ARE FILLED ELECTRICALLY CONDCTIVE CORROSION INHABITANT WITH A JOINTING COMPOUND AND CAPPED.

NOTE :

1) COMBINATOINS OF BI-METALLIC COMPRESSION JOINTS ARE DESIGNED ON THE BASIS OF CURRENT CARRYING CAPACITY OF INDIVIDUAL CABLES.

2) IN CASE ADDITIONAL COMBINATIONS ARE REQUIRED SAME MAY WILL BE PROVIDED AGAINST SPECIFIC REQUEST.

3) SHAPE SIZE AND DIMENSIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE.

Non Tension Bi Metallic Compression Joints

CONDUCTIVE MATERIAL :

ALUMINIUM BARREL 99.6%

COPPER PALM 99.95%

FINAL METAL STATE FULLY ANNEALED INCLUDING JOINT

JOINING METHOD FRICTION WELDING, WELDING AREA MORE THAN NOMINAL CONDUCTOR AREA.

FINISH NATURAL.

CONDUCTIVITY

ALUMINIUM 61.8% IACS (MIN)

COPPER 99.7% IACS

ALUMINIUM BARRELARE CHEMICALLY TREATED TO REDUCE CONTACT RESISTANCE AND CORROSION AND ARE FILLED ELECTRICALLY CONDCTIVE CORROSION INHABITANT WITH A JOINTING COMPOUND AND CAPPED.

NOTE :

1) COMBINATOINS OF BI-METALLIC COMPRESSION JOINTS ARE DESIGNED ON THE BASIS OF CURRENT CARRYING CAPACITY OF INDIVIDUAL CABLES.

2) IN CASE ADDITIONAL COMBINATIONS ARE REQUIRED SAME MAY WILL BE PROVIDED AGAINST SPECIFIC REQUEST.

3) SHAPE SIZE AND DIMENSIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE.

Bimetallc Connector

Description / Specification of Bimetallc Connector

We are involved in offering a wide range of Bimetallc Connector to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Bimetallc Connector. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Bi Metallic Pin Connectors

CONDUCTIVE MATERIAL :

ALUMINIUM BARREL 99.6%

COPPER PALM 99.95%

FINAL METAL STATE FULLY ANNEALED INCLUDING JOINT

JOINING METHOD FRICTION WELDING, WELDING AREA MORE THAN NOMINAL CONDUCTOR AREA.

FINISH NATURAL.

CONDUCTIVITY :

ALUMINIUM 61.8% IACS (MIN)

COPPER 99.7% IACS

ALUMINIUM BARRELARE CHEMICALLY TREATED TO REDUCE CONTACT RESISTANCE AND CORROSION AND ARE FILLED ELECTRICALLY CONDCTIVE CORROSION INHABITANT WITH A JOINTING COMPOUND AND CAPPED.

NOTE :

1) COMBINATOINS OF BI-METALLIC COMPRESSION JOINTS ARE DESIGNED ON THE BASIS OF CURRENT CARRYING CAPACITY OF INDIVIDUAL CABLES.

2) IN CASE ADDITIONAL COMBINATIONS ARE REQUIRED SAME MAY WILL BE PROVIDED AGAINST SPECIFIC REQUEST.

3) SHAPE SIZE AND DIMENSIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.